Re-Steel Tool to Plate (TTP) repurposes obsolete Invar tools into Invar plate.

- Re-Steel extracts scrap and end-of-life composite tools from Prime and tooling contractor facilities.

- Re-Steel then breaks down, remelts, and converts the extracted scrap and end-of-life composite tools into new, high-quality plate to support future composite structures tooling applications.

- This closed-loop supply program produces circularity of critical materials, cost savings, reduced environmental impacts, and reduced supply chain and pricing risks, by localizing a global supply chain within the Prime’s or subcontractor’s operations.

- No cash outlay to Prime because tooling contractor pays service fee for repurposed plate at price per pound substantially below market.

- TTP conserves natural resources (nickel, iron, water, and energy sources) and reduces carbon output and mining of raw materials.

- Alternatively, extracted composite tools can be stored and catalogued by RE-Steel at strategically located facilities for customers’ future use or conversion decisions.

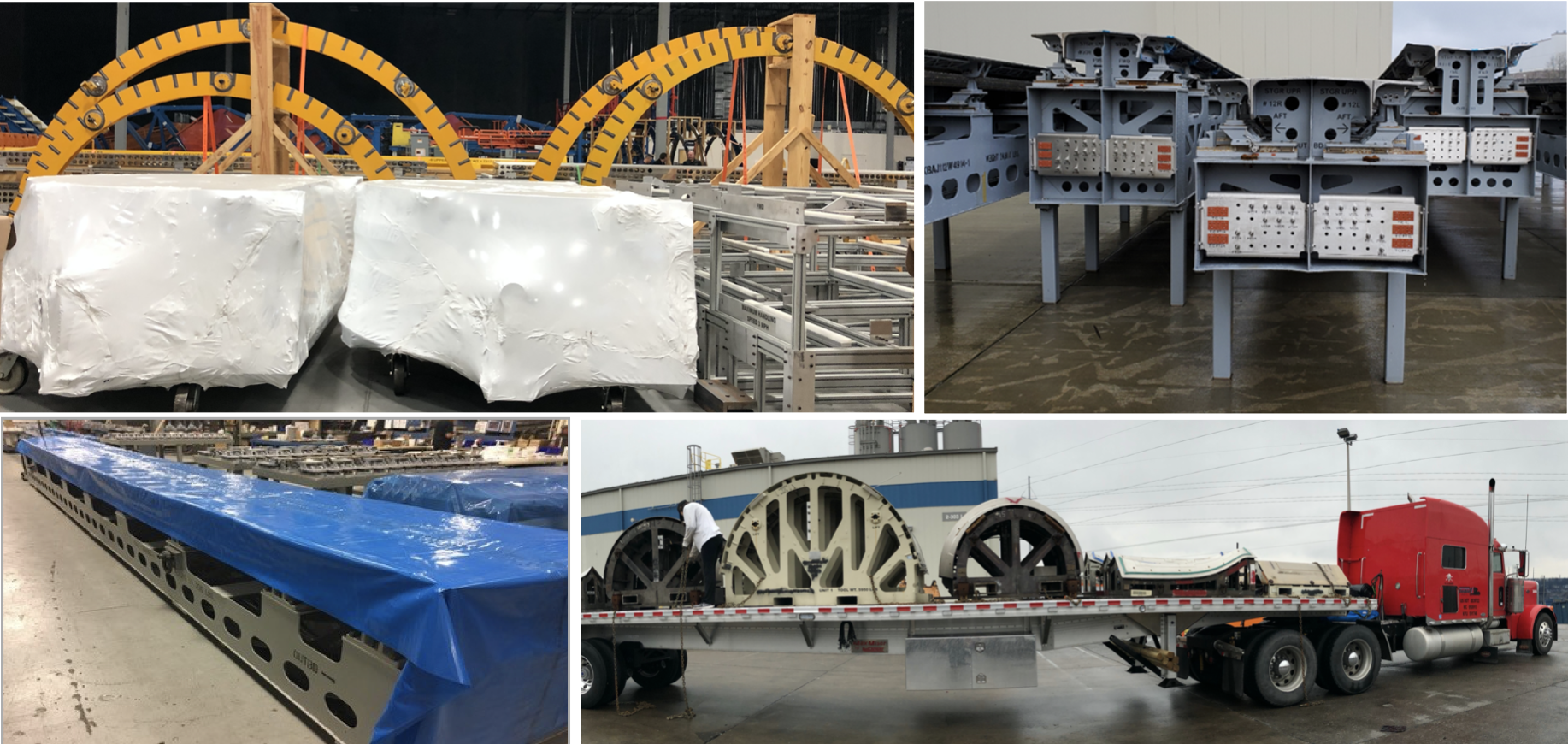

Recycle Programs for Tooling Fabricators

Composite Tooling & Scrap collected at customer locations

- No charge for hauling or provision of equipment

- Re-Steel Scrap bins on-site at customer locations

- Certified weight tickets

- Credits may be applied to customer invoices or exchanged for new Invar products

Composite Tooling materials managed and converted by Re-Steel:

- Invar

- 6061 Aluminum

- Graphite

- BMI

- Carbon Steel

- Kirksite

Re-Steel TTP Program

50335 Patricia Ave Chesterfield, MI 48051

[email protected]

+1-303-691-9053