Re-Steel produces invar tool kits for the fabricators of composite structures in the aerospace industry. Re-Steel’s tool kitting facility is conveniently located near Detroit, Michigan. The facility combines the data management of 3D and 2D files, nesting, cutting, labeling and packaging of invar tool kits ready for immediate fabrication. The result for our Primes and Tier 1 customers – cost savings, more control of their invar supply chain, and reduced lead times for a more sustainable, modern, and efficient Invar procurement process.

Re-Steel’s state-of-the-art technology and software allows for conversion from 3D CAD models using Catia or Step to export to 2D DXF files prepared for cutting to net shapes. Re-Steel uses the industry’s most efficient nesting algorithms to minimize material loss and maximize efficiency. HD Plasma and Waterjet cutting methods at Re-Steel’s Michigan facility hold tight tolerances in order to exceed customer requirements. The tool kits are labeled, professionally packaged, and shipped domestically or internationally.

Re-Steel’s expertise and experience managing invar in the composite structure supply chain make us uniquely positioned to more sustainably and cost-efficiently manage, produce, and deliver invar plates and tool kits to fabricators of composite structures in the aerospace industry. Please contact Tyler Streetman or Zach Tedeschi at 303-691-9053 or e-mail at [email protected] to discuss using the Re-Steel’s tool kits program for your business.

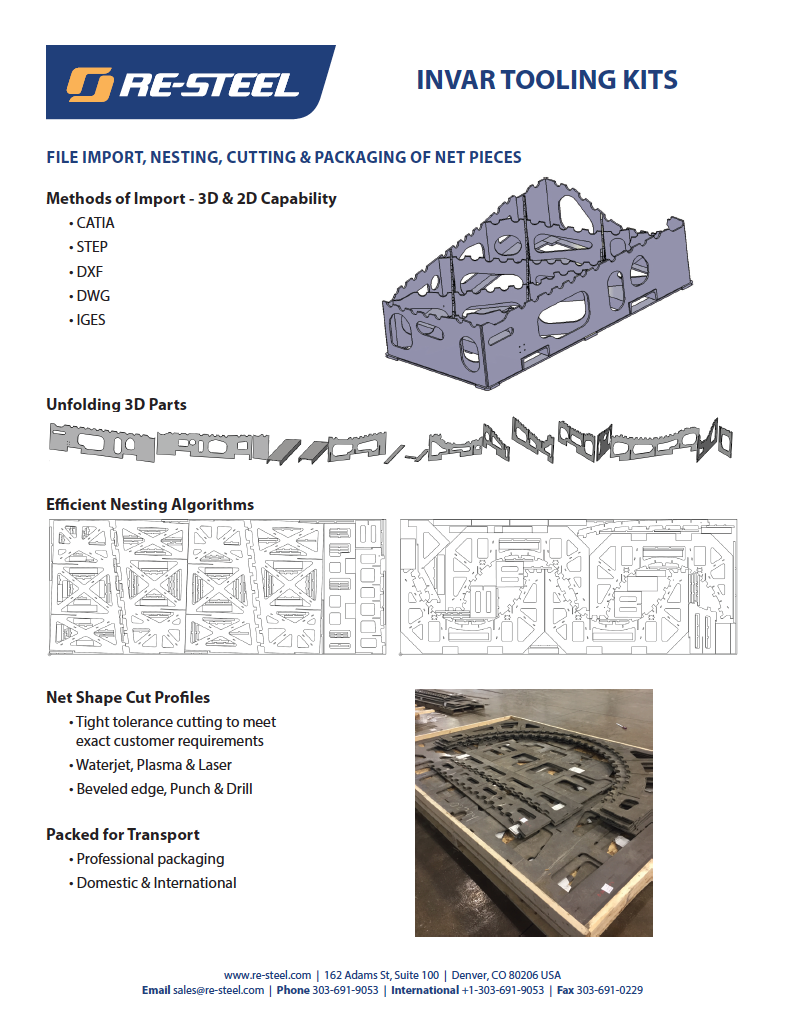

File Import, Nesting, Cutting & Packaging of Net Pieces

Methods of Import - 3D & 2D Capability

- CATIA

- STEP

- DXF

- DWG

- 3D-drawing

Net Shape Cut Profiles

- Tight tolerance cutting to meet exact

customer requirements - Waterjet, Plasma & Laser

- Beveled edge, Punch & Drill

Packed for Transport

- Professional packaging

- Domestic & International

- Net-Shape-Cut-Profiles

Unfolding 3D Parts

Efficient Nesting Algorithms